Ergonomics in workstation in industry and, more broadly, well-being at work have become central issues. However, associating industry with professional comfort is not always automatic. The industry suffers from a poor reputation as a laborious sector. However, it is also a field that allows for a great deal of innovation.

For several years, virtual reality has been helping industrial professionals become more efficient and productive. Immersive technologies are relevant tools for improving working conditions and ensuring a better future for employees and the company.

Why is ergonomics crucial in the industry ?

Increased arduousness at workstations

According to a study published in 2021 by the Ministry of Labor, one-third of French employees are exposed to strenuous or tiring postures. Numerous other statistics demonstrate the current laboriousness of work.

The industrial sector alone is a source of many problems: noise pollution, joint pain, pollution exposure, and eye tireness. The industry must address the issue of laboriousness to continue being a thriving and innovative sector.

Cases increases of musculoskeletal disorders

Currently, 20% of workplace accidents are due to back pain, and 30% of work absences are related to musculoskeletal disorders (MSDs).

These continuously increasing work absences inevitably lead to absenteeism and a decrease in overall productivity for companies.

Employees also suffer long-term health repercussions. For older workers, MSDs can result in work incapacity and plunge them into job insecurity. Beyond the age of 45-50, it becomes difficult to reintegrate professionally.

Ergonomics in the workstation in industry discussed

Due to all these factors, the industry is losing its appeal.

Consequently, workplace well-being became a crucial area of focus and optimization for industrial professionals. Then, it’s essential to delve deeply into the ergonomics of workstations.

Motivations for addressing these issues are related to health, but also to costs: in 2017, work absences and accidents cost French companies 2 billion euros. Thus, taking actions to improve ergonomics of industrial workstations should make it possible to revitalize a suffering sector.

How does virtual reality contribute to evolve ergonomics of industrial workstations ?

Work with real-time data, test new hypotheses and iterate

Virtual reality has already demonstrated its power and usefulness in industrial design, but its usefulness in improving arduousness and optimizing the workstation is also preponderant.

By immersing themselves in a virtual environment, engineers can visualize their product in 3D, and above modify it and collaborate easily with many. The same applies when it comes to establishing the components and accessibility conditions of a workstation.

VR offers numerous advantages for industrial professionals, including being able to rethink and improve the ergonomics of a workstation, regardless of the technical requirements on the position. We can therefore rely on data and new processes such as :

- Obtaining more precise and real-time data

- Easier detection of risks along a production line

- Better identification of malfunctions through virtual simulations

- Reducing workplace accidents and occupational diseases

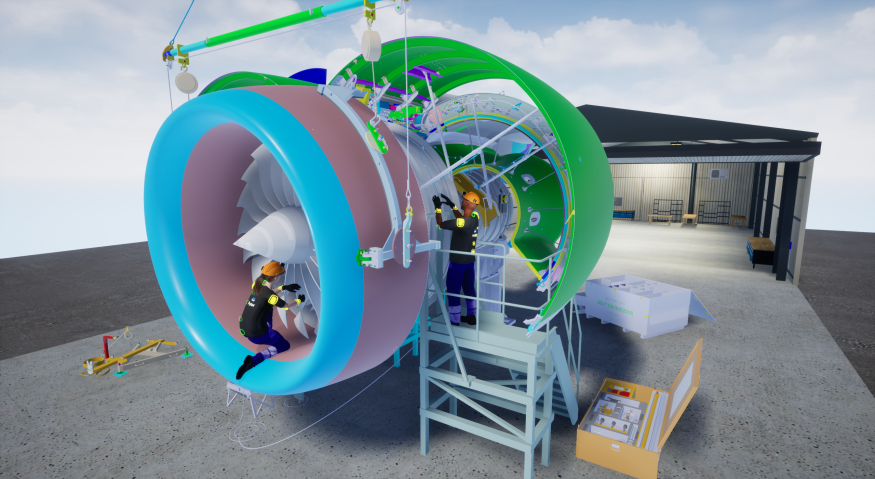

SkyReal places realistic virtual mannequins in full-scale work environments.

Validate the accessibility and ergonomics of a workstation from the design phase

The ergonomics of a workstation must be verified during the design phase.

In this contexte, design review becomes the focal point for controlling and making modifications to a workstation before declaring it operational.

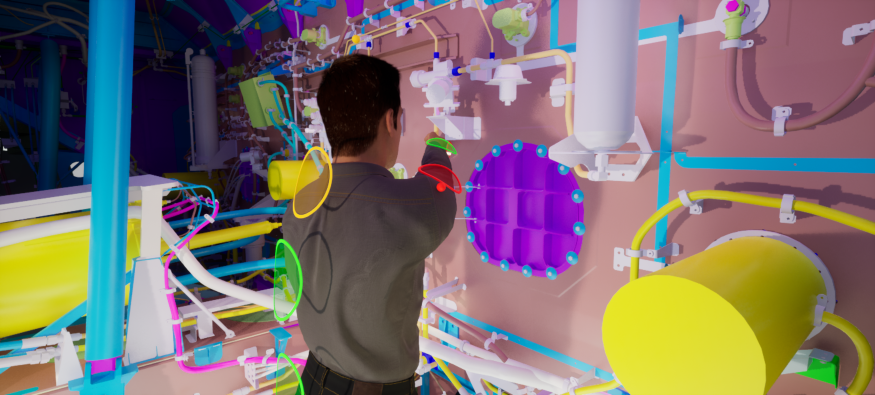

For example, when browsing an industrial site simulation, you can:

- Insert annotations in the virtual environment, around the workstation

- Make changes live, in collaboration with colleagues

- Check a production line

- Identify potential hazards and risks

Virtual reality will then make it possible to test the ergonomics of the workstation by immersing a user in a digital simulation. He will thus be able to interact with this station and its environment, at 1:1 scale.

This immersive testing phase leads to better anticipation. Engineers can identify errors or malfunctions, iterate and save time and money.

SkyReal’s solution, using VR design reviews, makes it possible to address this problematic of workstation accessibility present in many industrial sectors.

Better analyze postural and biomechanical constraints

Furthermore, the SkyReal VR solution’s virtual manikin option lets you put yourself in the shoes of an industrial operator and test a workstation in real-life conditions to observe more elements.

Actually, the software is able of analyzing postural and biomechanical constraints based on the stress on joint angles as a function of the postures performed. In this way, we can assess the risk of MSDs, while checking accessibility, for example.

Thanks to virtual manikin, we can also anticipate more precisely the elements of a workstation and anticipate what could hinder or even injure the operator, thus preventing accidents in the workplace.

Virtual reality, a support tool for the ergonomicst

VR is a valuable asset for industrial professionals. However, at SkyReal, we believe that it is primarily a tool for the ergonomist and by no means replaces their work.

Our solution assists them by providing a report with numerous data points. It helps them identify the body parts involved in specific postures and areas that pose long-term risks.

As a result, he can identify workstations that require excessively demanding postures and adapt them accordingly. VR aids the ergonomist in visualizing problems and therefore, finding appropriate solutions for the well-being of operators.

SkyReal offers the production of comprehensive ergonomic reports on complete work sequences, enabling the rapid detection of processes that contribute to musculoskeletal disorders (MSDs).

Obtain highly accurate data by replicating the real world

Through virtual reality, the user is immersed in a virtual environment that replicates the real world. In this digital universe, they can replicate the tasks performed by an operator on a daily basis.

A battery of technologies collects physiological data, such as motion capture, electromyography, electrodes, and force sensors.

Other subjective indicators provide the ergonomist with an evaluation of sensory and motor factors such as muscle fatigue and posture discomfort.

A possible future for industrial ergonomics

Today, one of the areas to be addressed is the improvement of of the ergonomics of the workstation in many industrial sectors.

Virtual reality is an innovation tool, offering new uses and a concrete solution to this industrial problem. However, it should also be used as a support for analyzing existing structures.

VR, as well as AR (augmented reality), can be used to capture data and verify the compliance of existing constructions, managing potential on-site risks.

In the near future, we can even envision ergonomists using virtual reality to conduct remote interventions based on a digital model that indicates the worker’s movements.